Largest producer of petroleum jelly

Since its founding in 1997, Navid Noor Polymer has emerged as a premier manufacturer of high-quality petroleum jelly, oil, wax, and advanced cable protection compounds. With a strong emphasis on quality, integrity, innovation, and sustainability, the company has grown from a modest beginning into a global leader. Serving the pharmaceutical, cosmetic, and industrial sectors, Navid Noor Polymer is committed to meeting the highest industry standards, fostering transparency, and continuously advancing through cutting-edge research and environmentally friendly practices.

High-Quality soft paraffin or Petroleum Jelly Grades for Pharmaceutical and Cosmetic Applications

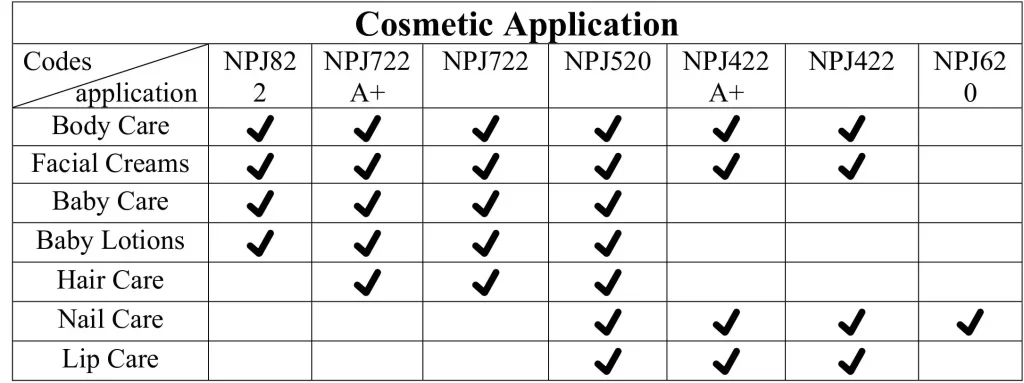

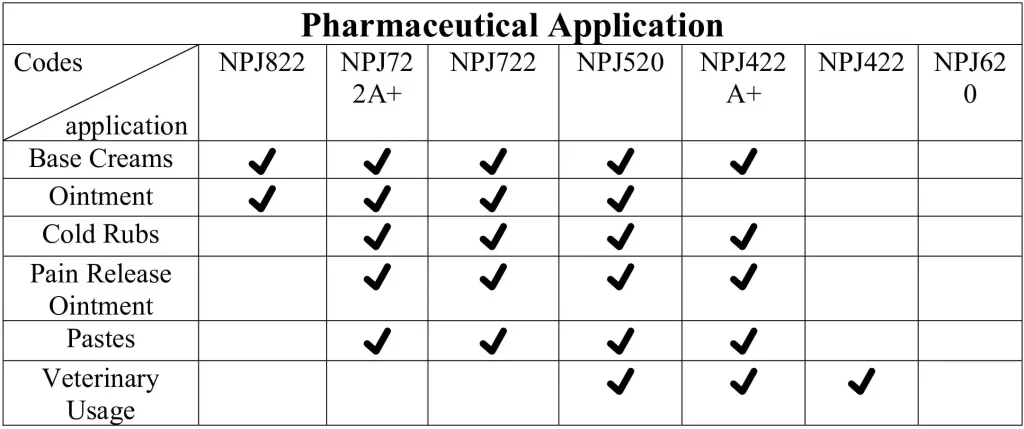

Wide range of Petroleum Jelly application in Pharmaceutical and Cosmetic industry might be well-known to all. Navid Noor Polymer Co. as the leading manufacturer and exporter of Petroleum Jelly provides wide range of grades including NPJ822, NPJ722A+, NPJ722, NPJ522, NPJ422A+, NPJ422, NPJ 620.

white petrolatum

White petroleum jelly, also known as white petrolatum, is a time-tested and multipurpose skincare product with a wide array of applications. Derived from petroleum, this translucent, semi-solid substance has been a staple in households and industries for generations. In this article, we will explore the various uses and benefits of white petroleum jelly, highlighting its versatility and effectiveness in skincare, medicine, and beyond.

Certified and approved quality

1. Skin Moisturizer

One of the primary uses of white Noor petroleum jelly NPJ422 is as a moisturizer for the skin. Its occlusive properties create a protective barrier on the skin’s surface, preventing moisture loss and locking in hydration. This makes it an excellent remedy for dry and chapped skin, especially in harsh weather conditions. Regular application can help maintain soft, supple, and nourished skin.

2. Healing Properties:

NPJ722 Pharmaceutical snow white petroleum jelly’s soothing and gentle nature makes it a popular choice for promoting skin healing. It can aid in the recovery of minor cuts, burns, and scrapes by protecting the affected area and providing a conducive environment for natural healing.

3. Lip Balm:

Chapped and dry lips are a common problem, especially in colder months. NPJ722 Noor White petroleum jelly is an effective and cost-efficient lip balm that helps alleviate dryness, cracking, and discomfort. Its non-toxic formulation makes it safe for all ages.

4. Makeup Remover:

As a gentle yet effective makeup remover, NPJ522 & NPJ722 white petroleum jelly effortlessly breaks down makeup, including waterproof mascara and long-lasting lipsticks. Its hydrating properties ensure that the skin remains nourished during the cleansing process.

5. Hair Care:

Luminoil White petroleum jelly can be a beneficial addition to hair care routines. Applying a small amount to the ends of the hair can help tame frizz and split ends, resulting in a smoother and healthier appearance. It can also be used to protect the scalp from the harsh effects of hair dye during at-home coloring.

6. Diaper Rash Prevention:

For parents and caregivers, Noor Orchid NPJ722 white petroleum jelly is a trusted ally in preventing and soothing diaper rash. By forming a protective barrier, it shields the baby’s delicate skin from moisture and irritation.

7. Tattoo Aftercare:

Many tattoo artists recommend NPJ petroleum jelly for tattoo aftercare. Its gentle formula helps keep the tattooed area moisturized, aiding in the healing process and preserving the vibrancy of the ink.

8. Lubricant:

In addition to skincare, NPJ620 yellow petroleum jelly serves as an effective lubricant for various purposes, such as facilitating the insertion of earrings, preventing chafing during physical activities, and lubricating small household items. Industrial petroleum jelly in Navid Noor Polymer has a high MOQ and needs a buyer’s manufacturing license to ensure the usage will be for industrial lubrication only.

Navid Noor Cosmetic and Pharmaceutical Petroleum Jellies

NOOR Petroleum Jellies are widely used in the cosmetic and pharmaceutical industry, where they are employed as processing aids, as softener for adjusting hardness, in many lotions and creams (e.g. cleansing milk, lipid-replenishing cosmetics and sun protection agents). They act as the base for creams, lipsticks, rouge and eye cosmetics such as eye-shadow, eyebrow pencils and mascara.

Solid paraffins and petroleum jellies are essential components in formulations of skincare products. They help enhance the health of the skin by protecting it from dehydration.

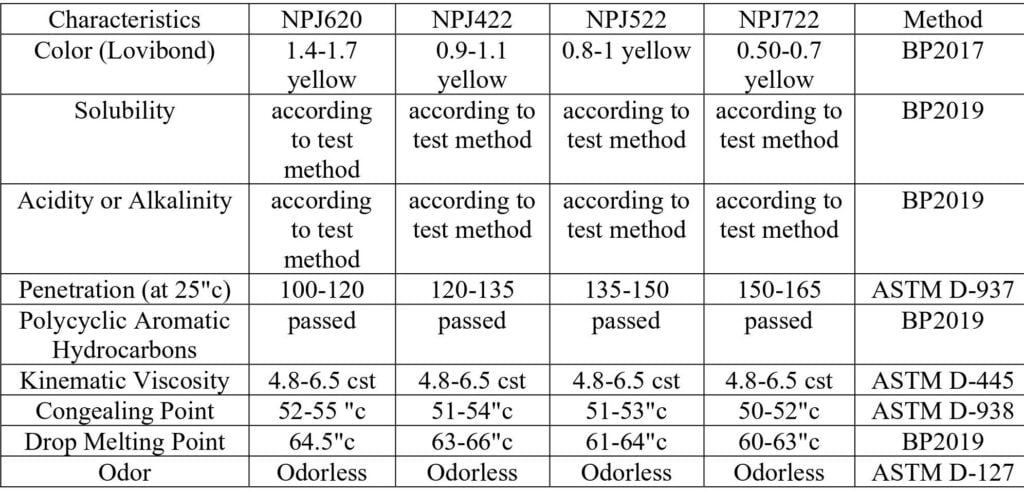

Navid Noor petroleum jellies are ointment-like, odorless, homogeneous mixtures of high-purity, hydrogenated, predominantly branched, saturated hydrocarbons. They come in snow- white, off-white and yellow pharmaceutical quality.

NPJ822 & NPJ722 are very high-grade petroleum jellies with excellent oil-binding capacity, especially for the pharmaceutical industry.We have special grades which are particularly resistant to heat and suitable for countries with tropical climates.

Navid Noor Pharmaceutical petroleum jellies are mainly used for base material for ointments, eye creams and hair-care, the main component of skincare creams, hand-cleaning pastes, body lotions, hand and skin creams. baby care and eye make-up. Due to their high purity, white pharmaceutical petroleum jellies are used in most applications today. As a responsible producer, Navid Noor promotes white petroleum jellies for pharmaceutical and cosmetic applications of all kind.

Petroleum Jelly COA

Packing:

In 55 kg or 175 Kg new steel drums with inside or without inside plastic cover. Ring tightly sealed and as per the customer’s requirements.