Vaseline for Industrial Uses in Industry

In the beginning:

Within the domain of industrial lubrication, the application of industrial-grade Vaseline has become a fundamental principle, demonstrating its multifaceted utility in diverse industries. This article thoroughly examines the various functions and benefits linked to incorporating industrial Vaseline into lubrication procedures. It emphasizes this substance’s critical significance in enhancing machinery’s performance and durability.

Properties of High-Performance Lubrication:

Industrial Vaseline, characterized by its exceptionally pure composition, serves as a dependable lubricant for apparatus operating in the industrial sector. The lubricating properties inherent in the material aid in the reduction of friction, thereby guaranteeing seamless operation in a wide range of apparatus components and gears that operate in diverse conditions.

Stability at Extreme Temperatures:

An essential characteristic of industrial Vaseline is its exceptional resistance to changes in temperature. Due to this attribute, it is ideally adapted for industrial applications in which apparatus functions in environments of extremely high temperatures. The capacity of the lubricant to preserve its viscosity and deliver consistent lubrication aids in the improvement of equipment dependability and effectiveness.

Protection against corrosion and wear resistance:

Industrial vaseline functions as a corrosion-preventing barrier, ensuring that metal surfaces remain unaffected by the detrimental consequences of moisture and oxidation. Due to its inherent resistance to corrosion and capacity to mitigate erosion, this substance is critical for lubrication formulations targeting heavy-duty industrial equipment. Moreover, it effectively extends the operational longevity of machinery.

Gasket and Sealant Compatibility:

Industrial vaseline is an exceptional lubricant in environments where efficient sealing is critical due to its compatibility with gaskets and seals. It maintains seal integrity and prevents leakage, thereby enhancing the dependability of equipment in sectors including manufacturing, automotive, and aerospace.

Repeal of Water and Contaminants:

Concerning industries The water-repellent characteristics of Vaseline are crucial in situations where moisture exposure is an issue. The formation of a protective barrier, it impedes the ingress of water and hinders the harmful impacts of contaminants, thereby guaranteeing uninterrupted lubrication effectiveness in vital industrial operations.

Application Across a Variety of Industries:

Vaseline, due to its versatile nature, can be effortlessly incorporated into an extensive range of industrial lubrication applications. Servicing a variety of industries including automotive manufacturing, industrial equipment, and precision engineering, this product’s adaptability ensures a consistent and dependable lubrication solution for their particular lubrication requirements.

Maintenance and Equipment Reliability Improvements Efficient operation:

The utilization of industrial Vaseline in lubrication procedures improves the dependability of machinery by decreasing friction-induced degradation and mitigating the likelihood of unforeseen maintenance interruptions. As a consequence, maintenance efficiency is enhanced through the prolongation of equipment life cycles and the decrease in the frequency of interventions associated with lubrication.

In closing,

In summary, the incorporation of industrial Vaseline into lubrication procedures demonstrates its critical contribution to the improvement of criteria for industrial applications. In light of ongoing industry emphasis on efficiency, dependability, and equipment durability, industrial Vaseline maintains its significance as a fundamental component in the quest for optimal machinery performance and operational excellence.

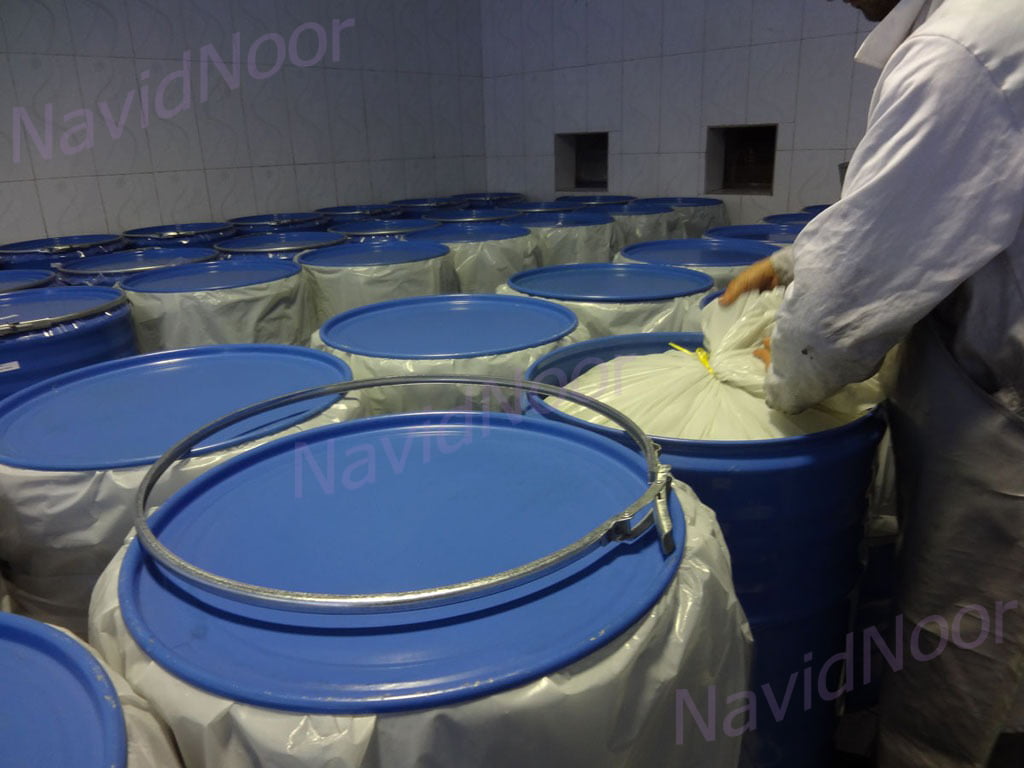

This is Kamran Malekian working in the petroleum jelly manufacturing industry for Navid Noor Company since 2013 I am eager to make content in this industry and have a good impact on professional users and people using cosmetic and pharmaceutical products.

No comment