Industrial Vaseline Article

Industrial Vaseline (Industrial Vaseline Grease): Full Technical Guide, Specifications & Industrial Applications

Industrial Vaseline by Navid Nor Polymer — The Leading Manufacturer in the Middle East

As the industrial sector continues to demand high-quality lubrication and protection products, Navid Nor Polymer has positioned itself as a premier producer of industrial vaseline, vaseline bulk and industrial vaseline grease in the Middle East. With a commitment to quality, global export capabilities and certified manufacturing, Navid Nor Polymer stands out in a crowded marketplace.

Why Navid Nor Polymer Is a Trusted Supplier of Industrial Vaseline Grease

Navid Nor Polymer invests significantly in refining processes and certification, ensuring its industrial vaseline grease meets stringent specifications needed for heavy‑duty applications. For customers seeking consistency, technical support, and regional availability, the brand offers reliability.

Certifications, Standards & Export Capabilities

Being a leading manufacturer, Navid Nor Polymer adheres to international standards — including, where applicable, NSF H1/HX‑1 certification for food contact applications — and offers global logistics from its Middle Eastern base. This combination of technical specification and market reach underscores its leadership.

Industrial Vaseline Grease Technical Specifications

Robust technical specification is key for industrial users evaluating industrial vaseline or vaseline industrial for their systems.

Standard Specification Table (Melting Point, Penetration, Flash Point, etc.)

Typical industrial petroleum jelly (industrial vaseline) may exhibit a penetration consistency of 110‑150 (0.1 mm) per ASTM D937 and a congealing point around 54‑58 °C.

Viscosity at 100 °C can fall in the range of 4.5‑6 cSt (ASTM D445) for certain grades.

Colour may be measured with Lovibond/IP‑17.

These are indicative figures—Navid Nor Polymer’s datasheet will specify the grade delivered.

Quality Grade Comparison: Industrial vs. White/USP

Industrial vaseline (vaseline industrial) is refined to fewer purification steps than pharmaceutical or cosmetic grades, resulting in lower cost and suitability for heavy‑duty applications rather than direct skin contact.

In contrast, white/USP grade petroleum jelly undergoes additional purification for colour, odour and purity, intended for medical or cosmetic use.

How Industrial Vaseline from Navid Nor Polymer Is Produced

Understanding how industrial vaseline grease is produced helps explain its performance characteristics.

Refining, Hydrotreating & Filtration

The base crude oil fraction is distilled, then heavy hydrocarbon fractions are processed (via hydrotreating, filtration) to produce semi‑solid petroleum jelly suitable for industrial use.

Strict Quality Control Certified for Industrial Use

After refining, the material is tested for penetration, viscosity, flash point, colour and contaminants to ensure it meets the technical requirements defined by industrial users. Navid Nor Polymer applies rigorous QC protocols to provide consistent batch‑to‑batch quality.

Industrial Applications of Industrial Vaseline Grease

Industrial vaseline and industrial vaseline grease serve a broad range of sectors due to their unique properties (hydrophobicity, film strength, inertness).

Machinery Lubrication

These products act as low‑friction lubricants in bearings, O‑rings, seals and slow‑moving components, especially where a film lubricant is required rather than a fluid oil.

Corrosion Protection & Protective Coating

Used on metal surfaces, fasteners, storage components or equipment exposed to humidity or marine environments, industrial vaseline provides a moisture barrier.

Mold Release & Sealing

In molding, casting or plastics processing, industrial vaseline serves as a release agent that prevents sticking of rubber, plastics and composite materials to molds.

Electrical Insulation

Low electrical conductivity and moisture‑resistance make industrial vaseline suitable for protecting cable joints, terminals and electrical connectors.

Printing, Textile & Leather Industries

Applications include lubricating print rollers, protecting leather/seal materials, providing moisture‑barrier coatings in textile/garment production.

Certified Food‑Related Applications

When provided in a certified grade (e.g., NSF H1/HX‑1), industrial vaseline may be used in food‑processing equipment, packaging or sealing scenarios. Navid Nor Polymer offers such variants for food‑industry customers.

Why Choose Navid Nor Polymer Industrial Vaseline Over Other Lubricants?

When evaluating industrial vaseline versus oils, greases or dry lubricants, several criteria apply.

Performance vs. Mineral Oils, Greases, Dry Lubricants

Industrial vaseline grease forms a stable semi‑solid film, is hydrophobic, and provides protection under low‑speed/high‑load conditions where mineral oils may run off or dry greases may fail. Its low oil bleed, chemical inertness and ability to remain in place make it a compelling option.

Application Decision Matrix

A decision matrix for selecting industrial vaseline might include: temperature range, speed/load, environment (moisture/dust), compatibility with materials (seals/plastics), maintenance interval and regulatory requirements. For environments with moisture exposure or where a protective film is needed, industrial vaseline frequently answers the requirement.

Advantages & Safety of Industrial Vaseline Grease

Benefits

Key advantages of industrial vaseline include excellent water‑repellency, film retention even under slow movement, compatibility with many seal materials, and cost‑effectiveness in bulk industrial applications.

Limitations

However, limitations exist: temperature range is narrower compared to some synthetic greases; dust accumulation may occur on exposed films; residue may require cleaning. Also, industrial grade versus cosmetic grade must be carefully selected for contact‑sensitive applications.

Safety Guidelines & Shelf Life

While industrial vaseline is inert and stable, correct storage (dry, cool, sealed containers), avoidance of contamination, and adherence to SDS protocols are vital. Ensure it is not used in human‑dermal or pharmaceutical contexts unless the grade is certified.

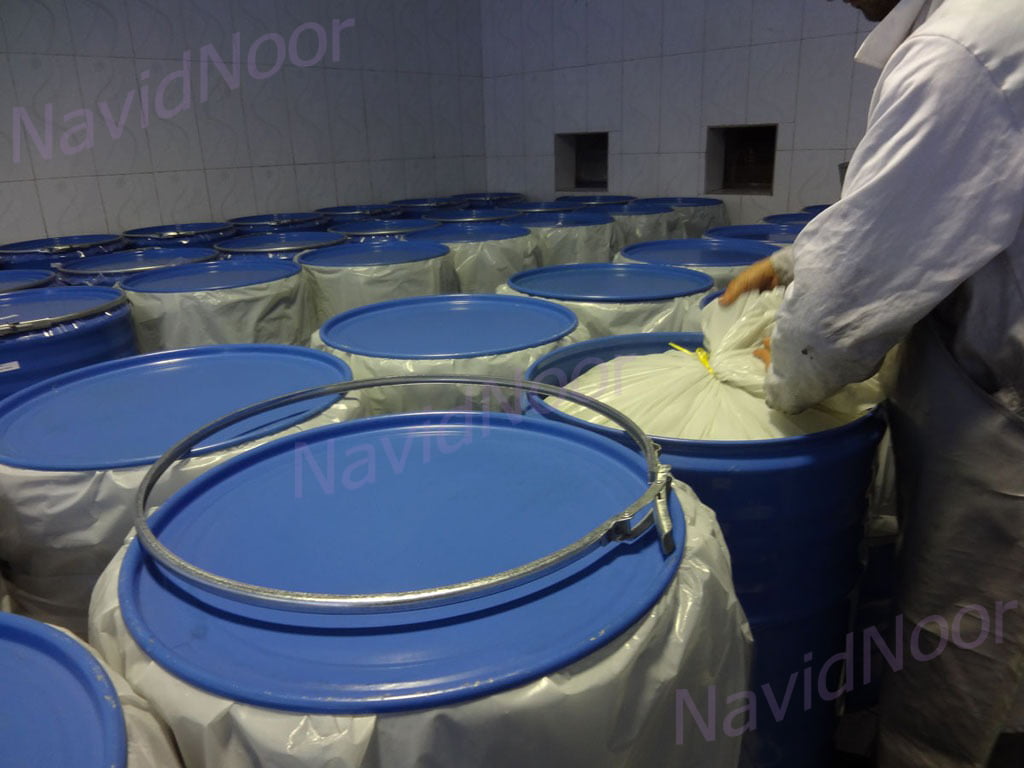

Packaging & Ordering Industrial Vaseline from Navid Nor Polymer

Packaging Types (Pails, Drums, IBC, Flexitank)

Navid Nor Polymer offers packaging formats suitable for industrial customers: pails (e.g., 25‑50 kg), drums (100‑200 kg), IBC or flexitank containers for bulk shipments. Bulk packaging reduces cost per kilogram and improves logistics efficiency.

Export Logistics & Delivery

With its Middle Eastern manufacturing base, Navid Nor Polymer services international export markets, adjusting packaging, documentation and shipping based on destination — a significant advantage for global buyers.

How to Request Prices & Technical Datasheets

To procure industrial vaseline or industrial vaseline grease, including supply solutions for petroleum coating companies, submit your application specifying the grade required (e.g., temperature rating, penetration, food certification). Navid Nor Polymer provides technical datasheets (TDS), safety data sheets (SDS) and COAs upon request.

Industrial Vaseline FAQ — Expert Answers

Food Contact Safety

Only use grades certified for food contact (e.g., NSF H1/HX‑1). Standard industrial vaseline may not be food‑safe unless explicitly certified.

Temperature Range

Industrial vaseline typical congealing points are ~54‑58 °C; above that, behaviour may change and specialized high‑temp greases may be required.

Material Compatibility

While industrial vaseline is compatible with many materials, some plastics or rubbers (e.g., certain PP, EPDM) may not be recommended without verification.

Mold Release Performance

As a release agent, industrial vaseline provides excellent results for plastics, rubber and metal molds — the film ensures clean separation and easy cleanup.

Market Outlook & Industry Trends

The global market for petroleum jelly is expected to grow at a CAGR of approximately 4.9% from 2024 to 2032.

In 2023, the market value was estimated at USD 525.1 million.

North America’s industrial petroleum jelly market in 2024 alone reached about USD 1.7 billion.

These numbers underscore the significant and growing demand for industrial‑grade petroleum jelly products worldwide.

Summary

For industrial users seeking high‑performance solutions, industrial vaseline, vaseline industrial, and industrial vaseline grease represent trusted options when sourced from a certified manufacturer like Navid Nor Polymer. With strong technical specifications, broad application versatility, and a supply chain optimized for global export, the product line addresses critical needs in lubrication, corrosion protection, sealing and more.

This is Kamran Malekian working in the petroleum jelly manufacturing industry for Navid Noor Company since 2013 I am eager to make content in this industry and have a good impact on professional users and people using cosmetic and pharmaceutical products.

No comment